50% longer tool life when turning

Walter Tiger·tec® Gold s viacvrstvovým, vysoko štruktúrovaným povlakom MT-TiCN

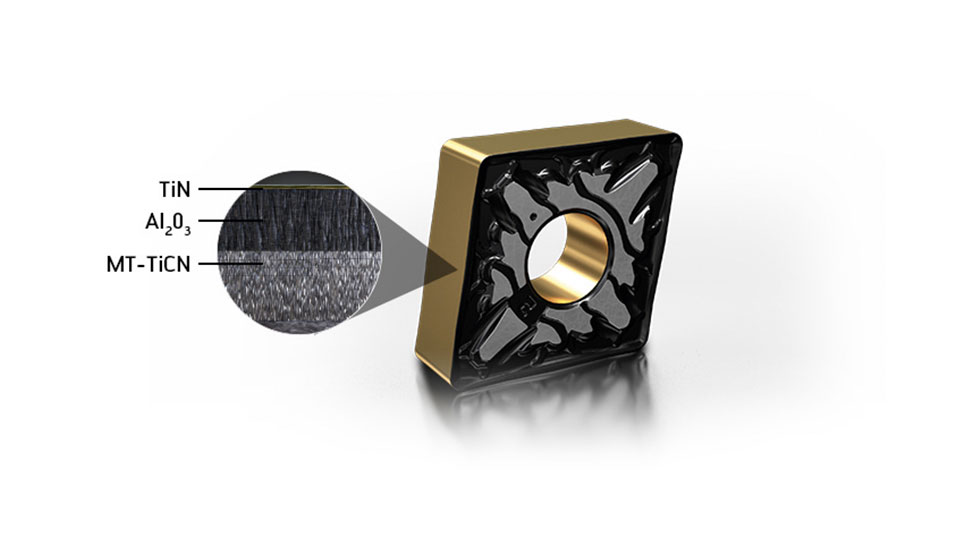

With grades WPP10G, WPP20G and WPP30G, Walter presents the new Tiger·tec® Gold indexable inserts, specially designed for turning operations. The goal was to reduce wear on the side by 30 to 60%. In fact, tool life increased by an average of 50% according to the results of more than 130 customer tests. The primary application is steels with a tensile strength of 600 to 900 N/mm2. In this new class, it is also possible to process light components from steels with a high tensile strength of 1000 to 1400 N/mm2, which are currently in trend. Interchangeable inserts are sure to be of particular interest to mass producers in the automotive, energy and general engineering industries, where inserts significantly reduce component costs. Wherever a range of materials are used, such as in the engineering industry, users can benefit from their versatility: Walter brings classes with nine geometries for optimized chip breaking on low-carbon materials with long chips (MP3) and for interrupted (RP7) on the market. Another key feature of Tiger·tec® Gold turning inserts is their excellent process reliability. This, in addition to their performance and tool life, is the result of their unique layer structure: The patented, highly structured MT-TiCN layer reduces flank wear and increases toughness thanks to its multi-layer structure that optimizes elasticity. The highly structured Al2O3 layer additionally increases the product's resistance to wear by craters. The top layer of gold color improves wear detection. The final multi-stage post-treatment of the inserts ensures a smooth front surface, less friction and a high level of toughness. The individually aligned grades make the inserts extremely versatile: WPP10G for continuous cuts and light interrupted cuts, WPP20G as a universal grade for 50% of applications and the durable WPP30G grade for interrupted cuts as well as unstable or adverse conditions.

Another key feature of Tiger·tec® Gold turning inserts is their excellent process reliability. This, in addition to their performance and tool life, is the result of their unique layer structure: The patented, highly structured MT-TiCN layer reduces flank wear and increases toughness thanks to its multi-layer structure that optimizes elasticity. The highly structured Al2O3 layer additionally increases the product's resistance to wear by craters. The top layer of gold color improves wear detection. The final multi-stage post-treatment of the inserts ensures a smooth front surface, less friction and a high level of toughness. The individually aligned grades make the inserts extremely versatile: WPP10G for continuous cuts and light interrupted cuts, WPP20G as a universal grade for 50% of applications and the durable WPP30G grade for interrupted cuts as well as unstable or adverse conditions.

Recent Comments